Following the recent announcement of the Government’s intention to remove diesel trains from the network by 2040, KEITH FENDER looks at how Alstom has developed a hydrogen-powered train that will lead to a trial in the UK within two years.

In early November, Alstom and the government of the German state of Niedersachsen (Lower Saxony) announced the first order for 14 of its new ‘iLINT’ hydrogen fuel-cell powered multiple units.

The order is worth around €90million (£80m) and includes a 30-year maintenance contract. Niedersachsen is funding €81.3m and the German Federal Government the remainder as part of a wider €250m national programme for hydrogen and fuel-cell technology.

Monthly Subscription: Enjoy more Railway Magazine reading each month with free delivery to you door, and access to over 100 years in the archive, all for just £5.35 per month.

Click here to subscribe & save

Twelve of the new trains will be built at Alstom’s Salzgitter factory (Germany) between 2019 and 2021 to operate alongside the two Class 654.1 prototype units which were showcased at the 2016 Innotrans exhibition in Berlin, and gained approval for test passenger service in late-2017.

The prototypes are due to start being used on the Buxtehude-Bremervörde-Bremerhaven-Cuxhaven route west of Hamburg during 2018. Alstom has already signed letters of intent for up to 44 more hydrogen- powered regional trains with three other German states.

Wider use in Europe

Alstom has also confirmed it is looking at opportunities to sell hydrogen-powered trains in the UK, the Netherlands, Denmark and Norway. The company’s aspirations are driven by the UK’s 3,000 vehicles, which is the second highest number of conventional DMUs in Europe (after Germany with more than 4,000).

All of the countries targeted have ambitious climate protection targets in place to reduce diesel emissions and carbon emissions generally. Alstom says it is actively talking to UK TOCs, ROSCOs and DfT about bringing in the new technology, and the RSSB announced in February that it is planning a hydrogen-powered train trial in the UK in late-2019 or early-2020.

Cutting emissions, carbon and particulates

One of the side-effects of diesel engines is they emit not only visible exhaust but also largely invisible particulates. Despite major advances in emissions control through the use of particulate filters and other technology, engines are still seen as a major source of carbon emissions and tiny particulates that are harmful to human health, especially in congested cities. The World Bank has estimated transport globally produces around 23% of total CO2 emissions and uses 28% of all energy. Most of this is road transport, with one billion cars worldwide now, currently forecast to grow to two billion by 2050.

The French Government ranks air pollution as the third biggest cause of deaths in the country, and recent studies have shown 95% of London residents experience air quality below legal minimum standards.

Several major European cities, including London and Paris, have announced their commitment to ensure a major area of their cities are zero emission by 2030. The idea of restricting emissions is not new – the New York City Government banned steam and internal combustion-engined locos on railways in Manhattan on health grounds as long ago as 1903!

Looking beyond the rail industry it was reported in January 2018 car manufacturers around the world have announced plans to spend $90bn over the next decade developing electric vehicles – the shift to electrically powered cars and trucks means battery technology will continue to develop while getting cheaper.

Use for passenger trains at the very least seems inevitable – the question will be how to power the batteries with on-board power (such as fuel cells) an alternative to plugging trains into the grid to recharge.

Why hydrogen?

In Germany hydrogen fuel cells have been presented as an alternative to overhead electrification of regional lines in the northern state of Schleswig-Holstein, where the region’s coalition government is promoting the concept to avoid the cost of overhead electrification, while removing diesel-powered trains is something all parties can support.

Wind-powered trains?

German transport ministers have suggested hydrogen could be 25% cheaper than diesel and be completely emission-free. Whether it is carbon-free depends upon the source of the electricity used to make the hydrogen. Hydrogen is abundant in nature making up part of the chemical composition of water along with oxygen, but separating out the hydrogen requires electrolysis – if the electricity comes from wind or solar power then the hydrogen produced could be genuinely emission free (this is Schleswig-Holstein’s plan as there are hundreds of wind turbines on land and even more out at sea).

If, as in some other parts of Germany, the electricity is generated by burning coal or gas then hydrogen-powered trains are unlikely to be either ‘greener’ or more economic to operate than conventional diesel or electric ones.

How does hydrogen power a train?

As you may recall from school science lessons, hydrogen can be very dangerous as it burns ferociously – the use of hydrogen in airships (to provide lift rather than as a fuel) ended after several disastrous crashes, most famously the Hindenburg at Lakehurst, New Jersey in 1937. So how can it be used safely to power a train (or a bus or truck)?

Just as a diesel-electric multiple unit or locomotive uses the diesel engine to generate electricity which powers the power traction motors, the new generation of hydrogen-fuelled trains use a hydrogen fuel-cell to generate electricity for the traction motors, with any spare energy generated – and crucially that created through regenerative braking – stored in batteries to provide yet more power. Alstom’s ‘iLINT’ has two 200kW fuel-cells mounted on the roof, but 1,300kW of lithium-ion battery power storage making it effectively a powerful two-car EMU.

The hydrogen fuel cell

The crucial part of a hydrogen-powered system is the fuel cell, which brings together hydrogen and oxygen molecules and converts the chemical potential energy (energy stored in molecular bonds) into electrical energy by (simplistically) mixing the molecules together within the fuel cell to generate an electrical (DC) current.

The fuel cells used for transport applications use proton-exchange membrane technology, which has a polymer-electrolyte membrane – in simple terms, a thin plastic film in water – as the electrolyte. Polymer is a chemical compound (similar to Teflon, which will be familiar to most readers as a coating for saucepans).

The technology isn’t new – NASA developed hydrogen fuel- cells and used them in the US Space programme from the early-1960s, and there have been hydrogen fuel cell-powered buses in London for several years. Also, some UK delivery companies are now using vans powered using fuel cells.

Currently, two firms – both Canadian – lead the world in producing hydrogen fuel cells for rail use. Alstom is working with Hydrogenics, while Siemens has separately announced plans to develop a hydrogen-powered version of its new ‘Mireo’ EMU design with Ballard, which has been supplying fuel cells for five years that have been used in early experiments powering locos and trams in China.

Alstom’s ‘iLINT’

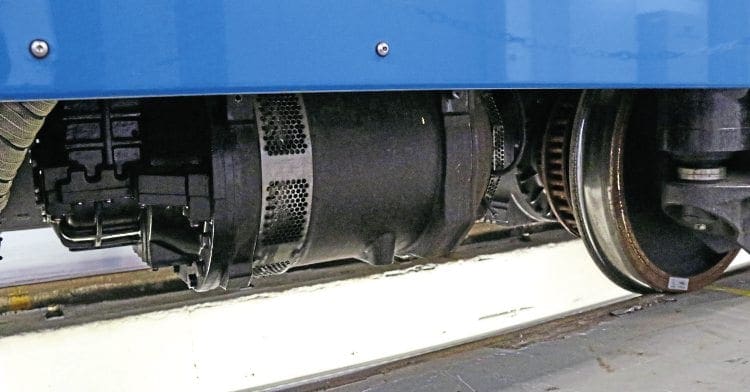

The two-car ‘iLINT’ prototype is based on the bodyshell and bogies of the existing ‘Coradia LINT54’ DMU (German Class 622). The interior seating moquette incorporates the chemical symbol for water (H2O) as the train runs on a mixture of hydrogen and oxygen, and produces only clean water as a ‘exhaust’ emission.

The ‘iLINT’ weighs 107 tonnes without passengers – nine tonnes more than even the most powerful DMU version (which has three diesel power-packs), reflecting the weight of the fuel cells and water plus the batteries to store ‘spare’ energy. The 140km/h ‘iLINT’ Class 654 uses two roof-mounted hydrogen fuel cells and onboard batteries to power two traction motors.

The two prototype units have been rigorously tested for a year, both on the Salzgitter factory test track and at Velim in the Czech Republic. They are currently on test in Germany and have received safety-case approval for test passenger service use.

Re-fuelling

The ‘iLINT’ is designed for regional services and should have a range of 800-1,000km between refuelling stops. Early tests suggest the ‘iLINT’ uses 0.25kg hydrogen per kilometre. Refuelling initially for the test operation in Germany will be from temporary storage facilities brought in by road.

The hydrogen gas is compressed and under great pressure (350 bar or more than 5,000psi) so it will take around 15 minutes to refuel the two fuel modules per train. Each fuel module can hold 90kg of compressed hydrogen and each two-coach train has two fuel storage modules and two fuel-cells

A hydrogen fuelling point planned for the first German depot to operate ‘iLINTs’ at Bremervörde will cost €10m. It is being built by German industrial gas supplier Linde (which owns BOC in the UK). Initially, the hydrogen will be brought from production sites at chemical works and transported by road. Longer-term alternative greener sources for the hydrogen are envisaged using electrolysis from water using wind energy (e.g. at night or when demand from the grid is low) on-site in the depot.

Safety

Alstom points out hydrogen is very safe if handled correctly, but if not used properly or if the system is damaged accidentally and leaks, there is a risk of fire. Alstom’s designers have thought about this and each vehicle has its own discrete fuel system – there are no inter-vehicle hydrogen connections.

Alstom deliberately put the hydrogen tanks on the roof of the train so in the event of a leak, the gas would vent upwards into the air and eventually dissipate. The logic for roof-mounting and venting upwards also means in a disaster scenario, where the fuel tanks caught light, the flames would also go upwards, which would give passengers and crew chance to escape.

New or retro-fit for the UK?

The hydrogen fuel cells and fuel tanks are housed in low-profile, roof-mounted units on the ‘iLINT’. While the UK loading gauge is less generous than in Germany, it seems possible roof-mounted units could be designed because the space required is probably no greater than that used for pantographs on conventional British 25kV AC EMUs.

Conversion of current DMUs is an option Alstom claims it would consider, although engineers at Salzgitter have questioned whether this would be economic as the trains would need to be stripped back to bare shells and completely re-wired.

Retro-fitting, by putting hydrogen tanks under the floor, appears unlikely as none of the safety benefits mentioned earlier would apply and significant steel protective sheeting would be needed to protect the tanks from flying ballast and other debris.

Pluses and minuses

A hydrogen-fuelled train may offer environmental and possibly even performance benefits compared to a conventional DMU. With powerful batteries it performs more like an EMU, and may also be cheaper to run per mile in the long term.

There are some potential downsides, too. The safe use of hydrogen in a rail environment has yet to be demonstrated, and some observers have questioned whether a train with hydrogen tanks on the roof can be safely used in tunnels. Interestingly, the trial routes in Germany to be operated by the new ‘iLINT’ have no tunnels.

Experience from the bus industry suggests both hydrogen fuel-cells and on-board batteries may not last as long as expected. In some cases UK bus operators are removing the batteries from hybrid buses and converting them to straight diesel buses as the expensive batteries need replacing sooner than expected.

As with any new technology the first hydrogen-powered trains will be relatively expensive as the fuel cells are made to order and new fuelling depots have to be set up.

Whether it will make economic sense to replace diesel trains in this way is too early to judge, but if in the long term major cities start banning diesel-powered vehicles – including trains – operators will have to find alternatives. ■

Read more News and Features at https://www.therailwayhub.co.uk/ and also in the latest issue of The Railway Magazine – on sale now!

The Railway Magazine Archive

Access to The Railway Magazine digital archive online, on your computer, tablet, and smartphone. The archive is now complete – with 123 years of back issues available, that’s 140,000 pages of your favourite rail news magazine.

The archive is available to subscribers of The Railway Magazine, and can be purchased as an add-on for just £24 per year. Existing subscribers should click the Add Archive button above, or call 01507 529529 – you will need your subscription details to hand. Follow @railwayarchive on Twitter.