Greensand Railway Museum Trust (GRMT) was formed in 2000 and completed restoration of Baldwin 4-6-0T WDLR No. 778 to steam in 2007 – the only operational Baldwin class 10-12-D in Britain, indeed the world, in as-built steam locomotive form. Now, the GRMT has its eyes firmly fixed on another ‘war veteran’ restoration project as chairman Cliff Thomas explains.

RESTORING No. 778 was a huge and expensive project for a small charitable trust. Thanks to donations and money raised during its first boiler ticket No. 778 was overhauled during winter 2015/16 and, with a new 10-year ticket, continues to steam at Leighton Buzzard Railway (LBR), having also visited France (Froissy-Cappy-Dompiere) and Apedale Valley Light Railway during 2016.

The GRMT is now progressing restoration of 40hp Armoured Simplex LR2182, built by Motor Rail and Tramcar Company of Bedford (MR461/1917).

Enjoy more Railway reading in the monthly magazine.

Click here to subscribe & save.

No. 2182 is a unique survivor and the perfect companion for No. 778. Both were built around the same time to assist the allied war effort on the Western Front in the First World War with complementary roles.

Sixty centimetre- (2ft-) gauge steam locomotives such as Baldwin No. 778 hauled essential supplies from standard gauge railheads 8-10 miles behind the front line as far forward as was reasonably safe, given a steam loco’s visibility to enemy observers.

The wagons continued to forward supply points or artillery batteries in shorter trains hauled by petrol-engined locos. There were a range of such internal combustion locos, including fully ‘open’ machines, Simplexes equipped with protective plates and similar locos equipped with full ‘armour’; 2182 is the sole survivor of this type with its original petrol engine.

The few existing photographs of 40hp armoured locos in France show them carrying numbers without the LR prefix, although this may have been specified in later orders. For this article, it will be referred to simply as 2182.

Built for war service

Motor Rail was a major supplier of locomotives to War Department Light Railways. They built 34 of this armoured type, although this might have comprised 27 armoured locomotives built as such, plus seven ‘conversion kits’ for open versions.

The company also produced 110 40hp Open types, 195 40hp Protected types and 749 20hp locos, including the above-mentioned 34 figure for Armoured, a total of 1,088 locos, or tractors as they were termed at the time.

Researchers have produced a Motor Rail Works list, but delivery dates for 40hp Simplexes are confusing. Motor Rail appears to have applied the ‘indent’ date on works plates rather than delivery date, and works numbers were not issued in sequence until mid-1917.

The first ‘Armoured’ tractor is believed to be MR422, dispatched to Longmoor on August 17, 1917. Locos from the same builder’s number sequence (423-429) constructed around the same time may have had armour fitted in France after delivery.

The next recorded Armoured tractors were MR460-465 (WDLR 2181-2186), delivered on March 24, 1918, more than a year after the Indent date (Feb 14, 1917) which appears on the works plates – these were the first of a batch of 26 locos delivered to France.

The National Army Museum donated a replica works plate for 2182 showing details as: ‘Motor Rail & Tram Car Co. Ltd. 79 Lombard Street, 461, London EC, W^D Simplex Patents, Indent No. LR 10227, Feb 14 1917’. This plate seems to have been cast from the original, so the date seems to refer to ordering rather than construction.

No solid information has emerged concerning 2182’s army service, but photographs exist of Nos. 2184 and 2187 on active service, the former also being completed on March 24, 1918, the latter two days later, implying 2182 probably arrived to serve on the French battlefields during the final year of the Great War.

A thumbnail background

Post-First World War, 2182 entered the hands of the disposal board at Richborough, Kent around May 1921, being bought by Furness Brick & Tile Co Ltd of Askham Brickworks, Askham-in-Furnaces, Lancashire (now Cumbria) around July of that year.

During the ensuing period of industrial service it lost its distinctive upper bodywork. It was disused by 1963 and at some stage went to Morgan’s, a scrap dealer at Barrow, and while at this yard seems to have lost its number plates, works plates (although at least two, possibly more, replica works plates exist – believed to have been made by Brian Gent), carburettor, brake handwheel and brass Dorman engine works plate.

Bought by Michael Jacob for £150 it entered preservation in 1971. After storage in Blaenau Ffestiniog, it moved to the nearby Narrow Gauge Railway Centre at Gloddfa Ganol in June 1978, then to the Museum of Army Transport at Beverley in September 1985, Mr Jacob donating it to the army on December 18, 2001.

While displayed at Beverley it appeared to be in original form, but this was an illusion. The ‘armour’ had been replicated in wood by Mr Jacob.

The Museum of Army Transport (institutionally separate from the National Army Museum [NAM]) closed to the public in August 2003. The NAM took a one-year lease on the Beverley premises to secure and audit the contents which had been exhibited under loan agreements, then arranged loans of the various exhibits to suitable hosts during late-2004/early-2005.

The army offered 2182 to Leighton Buzzard Railway, where it arrived on March 30, 2005. Sadly, the army’s contractors seriously mishandled the loco during the move, with the wooden roof and cab doors ripped off and one of the original end panels damaged. The army subsequently donated the historic loco – as it stood – to LBR.

Right loco, right railway

The ‘original’ Leighton Buzzard Light Railway had two of the armoured type in its fleet: LBLR Nos. 3 and 4 (MR478/LR2199 and MR468/LR2189, respectively) bought from the War Department around 1921, in addition to protected types or hybrid post-war rebuilds.

So, LR2182 represented a type which ran post-First World War on today’s LBR line together with historic local connections having been built in nearby Bedford.

A 2005 quotation for complete professional restoration estimated the cost as some £35,650. With numerous other projects in progress, LBR could not devote the resources needed and GRMT therefore offered to take on the project.

Ownership of 2182 officially transferred to the trust in January 2009, simultaneous with an agreement with LBR very similar to that covering No. 778 being signed.

Volunteers then constructed a new replica (again, in wood) upper part of the loco. By presenting the original appearance of 2182 the hope was to stimulate fundraising towards full restoration.

With the trust’s coffers emptied following restoration of No. 778 a promotional leaflet was prepared and some money raised, but the old adage that internal combustion does not tug the heartstrings in the same way as steam proved true.

Raising the cash for professional restoration (probably around £40,000 by this time) seemed unlikely so GRMT reappraised the project in early 2015, opting to undertake a basic restoration aimed at getting the locomotive able to move under its own power by its 100th anniversary in 2017.

Construction of replacement superstructure and other non-essential details would be postponed, the hope being evidence of a working chassis would stimulate interest and help raise more money to complete the project.

Pending possible grant applications and knowing it is unwise to dismantle any locomotive until you are ready to start putting it back together 2182 had been left intact.

Visual inspection of this kind of machine generally provides a good idea of what requires work and what should remain serviceable. Indications were the wheel bearings, axles, horn guides, axle box brasses and wheels (flanges and tread width) were in good enough condition, certainly for the light use envisaged under this ‘phase one’ concept.

‘Phase one’ restoration

Under the project leadership of Tim Ratcliffe (LBR museum diesels officer and one of the team that restored the NRM’s ‘Protected’ LR3098 to operation when it was on loan to Leighton Buzzard) this ‘phase one’ restoration would devote attention to the frames, gearbox, clutch, radiator and petrol tank; a new set of drive chains were also clearly needed.

The big unknown was the original 40hp Dorman 4JO 4-cylinder petrol engine (engine No. 6209), which was seized, but until stripped impossible to know the full extent of its problems.

GRMT was determined on restoration rather than taking the easy, and far cheaper option of fitting a modern diesel engine, therefore engine repairs had to be contracted to a specialist, but with volunteers willing to tackle much of the other work the estimated cost of this first phase was around £13,000.

An application for PRISM (Preservation of Industrial and Scientific Material) funding resulted in a grant ultimately worth £9,053 and with a further £500 (covering a new gear required in the gearbox) from the Museum Development – Bedfordshire Small Grants Scheme a start was made on dismantling.

Restoration starts with the engine

The engine, unused for more than 50 years, was sent to Coventry Boring and Metalling Ltd for stripping, assessment and repair. The stream of following bad news caused no surprise. Two of the four pistons broke apart on removal from the cylinder bores, cracks in the cylinder block, crankcase and manifold were revealed, the valves and guides were junk, the cone clutch was seized and these were just the larger components needing attention.

Stitch welding dealt with the cracks, four new pistons were produced (machined from solid aluminium) and the cylinder block line bored and machined to accept three pairs of main bearings and four new liners. Eight new valves and guides were also manufactured.

Coventry Boring also reground the crankshaft bearing surfaces, cleaned up and polished the camshaft lobes, re-machined the flywheel face, produced four connecting rod bushes and modified the connecting rods to suit the new pistons.

All this work emptied the trust’s coffers, leaving no cash to contract reassembly of the engine. Fortunately, Peter Thorne offered to undertake reassembly as a volunteer project. The engine components were taken to his home workshop, where his years of experience compensate for the absence of any written guidance as to how it all goes back together.

The clutch cone, which had defied all efforts at Coventry Boring to separate the individual components, was finally defeated at Alan Keef Ltd, which then fitted a new clutch lining – this was found in the LBR stores at Stonehenge Works and assumed to date from when these locomotives ran on the line in industrial days.

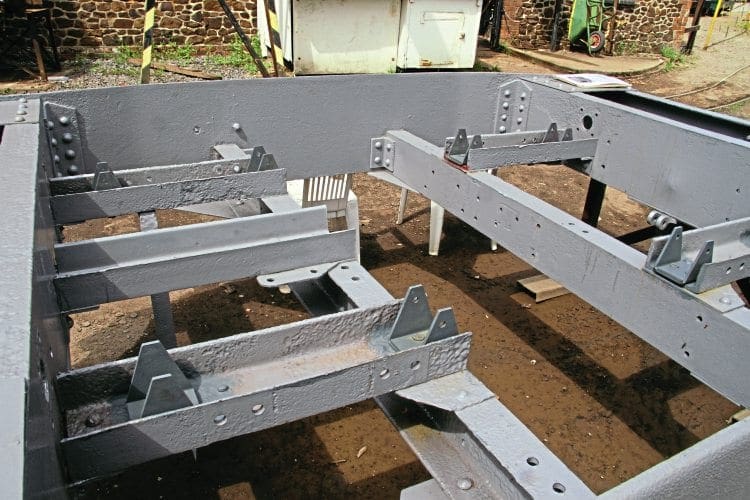

Meanwhile, the chassis was reduced to a bare riveted frame at LBR’s Stonehenge Works and professionally shot blasted in March 2016. Volunteers removed corroded steelwork, including some angle sections and several of the gusset frame reinforcements, and hot-riveted replacements into position.

With the immediate objective limited to 2182 moving under its own power, possibly hauling a few wagons, rather than a full restoration, as much material as possible was cleaned up and reused, although new oil pads, axlebox covers, spring hangers and a set of replacement leaf springs were needed.

On November 30, 2016 the wheelsets were lowered into the frames, the ensemble being turned the right way up to provide a rolling chassis.

The gearbox, removed with the engine, received attention from LBR volunteers. Its condition was fundamentally good, although it needed a new gear and bearings.

After reassembly the gearbox was installed in the frames on December 11, followed by refitting the end weights. Awaiting resolution is the broken and incomplete direction selector mechanism cover, which will need to be repaired, modified or replaced.

Although new drive chains are needed and the chain tensioning rods require repairs, the sprockets are serviceable.

New ‘free’ fuel tank

Quotations for professional repair of the radiator proved far higher than anticipated. Fortunately, LBR members Andy Forbes and Mick Taylor offered to dismantle, clean and reassemble it, managing to retain most of the original finned tubes supplemented by some new plain tubes, where they cannot be readily seen, the only cost being replacement rubber ferrules supplied by Alan Keef Ltd.

Further good news was an offer by ‘Shop 4 Tanks’ of Northampton to produce, free of charge, a new fuel tank. Manufactured from stainless steel it replicates the original exterior dimensions and shape, but with a smaller internal plastic tank to contain the petrol so it will not cost a small fortune to fill (the original tank had far greater capacity than will ever be needed in preservation) and should never corrode.

The original magneto has been repaired and a replacement carburettor sourced, although an inlet manifold adaptor plate needs to be designed and manufactured.

The engine cover and seat frame have been repaired and a new wooden seat constructed. Castings for the ends of the exhaust silencer have been found and a suitable tube obtained. Brackets and a tie rod to secure all the exhaust remain to be designed and manufactured, probably only after the cupola has been installed.

WILLIAM SHELFORD

Renewed appeal

While reassembly of the engine continues, as does other volunteer work requiring little or no expenditure, there is no further money available precluding further significant work.

How much cash is needed to complete restoration of this unique First World War veteran? Hard to say, but GRMT believe something in the region of £5,000 should cover all remaining expenditure – including new drive chains and ordering the steel components to replicate the all-important cupola roof. Compared with steam locomotive restorations this is almost paltry – but still has to be found.

This is an important locomotive and GRMT wants to avoid restoration stalling as 2182 approaches its 100th anniversary. A renewed appeal for donations is therefore being made in an effort to maintain momentum. ■

■ Readers can send donations (marked ‘2182 restoration’) to The Greensand Railway Museum Trust, c/o Page’s Park Station, Billington Road, Leighton Buzzard, Bedfordshire LU7 4TG. By completing a Gift Aid form, the tax can be reclaimed, increasing the donation value by 25%.

Defining Unique

LR2182 is a unique survivor in still having its original petrol engine. It is also the only surviving 40hp armoured Simplex in the northern hemisphere. There is one other of this type (albeit with a replacement engine) in Antigua, also dating from 1917, which found its way into service in the Antigua sugar industry and became identified as No. 8 Bessie.

In recent years Lawrence Gameson has cosmetically restored Bessie for display at a new heritage centre at Betty’s Hope Sugar Mill, Antigua as part of a partnership arrangement with the Museum of Antigua & Barbuda.

To complete this work Lawrence needed to view 2182 to establish dimensions and designs of items missing from Bessie (principally the driver’s seat and engine cowl). In turn, he was able to supply all-important information concerning the cupola roof (‘conning tower’ in the original patent) which GRMT needs to reproduce for 2182.

With this information, Phil Robinson (chairman of Moseley Railway Trust and an LBR member) produced a drawing for the cupola which can be passed to contractors to produce.

It may seem surprising considering the radically different (i.e. considerably hotter) climate in West Indies that the armoured cupola roof (somewhat akin to the turret of a tank) should have been retained on Bessie, but it was – raised by nearly 1ft above the curved plate end pieces on hefty angle brackets to provide additional headroom, and doubtless more importantly, greatly increased ventilation.

As a result Bessie has a slightly bizarre ‘colonial’ raised roof arrangement, her appearance further departing from originality by the cutting of large rectangular holes into the end plates – 2182 will definitely be able to stake a claim as the only armoured Simplex retaining its original protected appearance.

The ‘Tin Turtle’ appellation

Protected and Armoured 40hp Simplexes have tended to become generically known as ‘Tin Turtles’. Obviously deriving from their appearance, the tag is thought to be of comparatively recent origin. It is said that when LR3098 arrived at Leighton Buzzard on loan from the National Railway Museum in November 1990 someone (identity now forgotten) asked, “what is that”.

On being given a full explanation, they decided a shorter name was required and being partially armoured decided ‘Turtle’ was appropriate. Subsequently, Moseley Railway Trust created a ‘Tin Turtle’ web site and the tag has entered common usage.

On the face of it, in the grim conditions amid constant danger of the forward areas of the Western Front, where these locomotives were designed to operate, one might think the more protection a driver got the better he might feel.

However, it has been said the light railway crews in France preferred the ‘open’ tractors since in case of trouble they could jump off and take cover in the nearest shell hole more quickly.

The plating must have offered a measure of protection against bullets and shell fragments, but would not withstand a shell exploding close by, let alone a direct hit. Moreover, with the armoured locomotives having only small vision slits for the driver, reputedly being appallingly hot and noisy to drive with the doors closed and a petrol tank right beside the seat, one can see why they may not have been overly popular with those who had to operate them.

That said, the armoured locomotives bought by the Leighton Buzzard Light Railway Ltd around 1921 remained in original condition until scrapped in 1959. Perhaps in civilian use the protection from rain was appreciated rather more than any protection from bullets enjoyed in original use?

The Railway Magazine Archive

Access to The Railway Magazine digital archive online, on your computer, tablet, and smartphone. The archive is now complete – with 123 years of back issues available, that’s 140,000 pages of your favourite rail news magazine.

The archive is available to subscribers of The Railway Magazine, and can be purchased as an add-on for just £24 per year. Existing subscribers should click the Add Archive button above, or call 01507 529529 – you will need your subscription details to hand. Follow @railwayarchive on Twitter.